Wet clutch centrifugal carriers utilize a combination of wet clutch and centrifugal forces to provide superior torque performance in a variety of operating conditions.

The wet clutch centrifugal carrier uses a wet clutch in combination with centrifugal force to deliver torque.

This combination creates a perfect mechanical solution for dynamic loads and extreme environments.

Wet clutch centrifugal carriers are ideal for applications that demand most torque in a small package, while still providing smooth speed and precision.

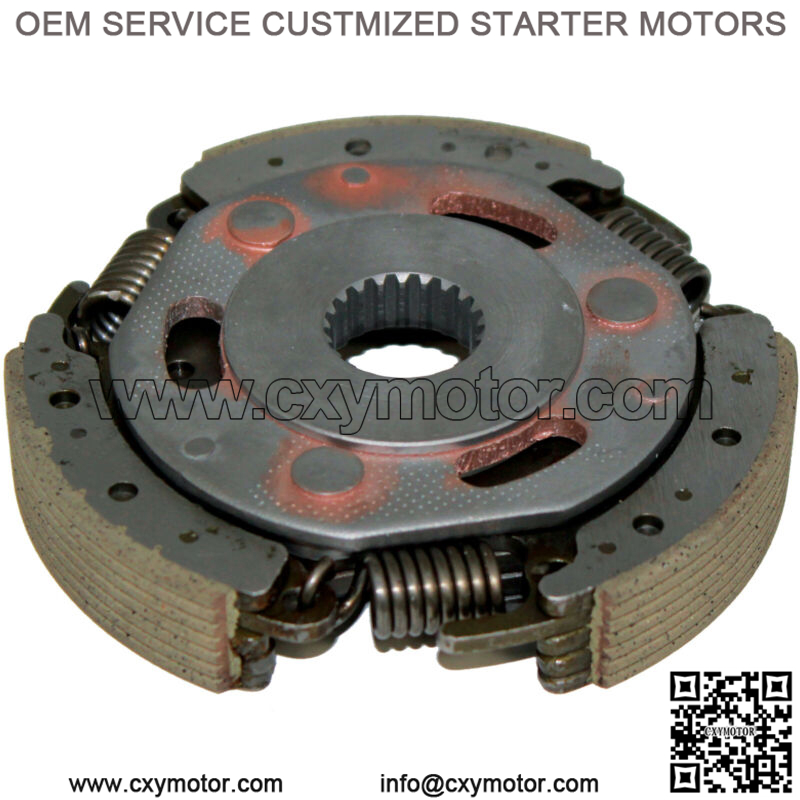

Wet clutch centrifugal carriers are made from high-quality materials, such as steel or cast iron, and feature a wide range of features to ensure optimal performance.

A wet clutch is housed within the centrifugal carrier, and the wet clutch disc is surrounded by a cap, which allows for greater torque output.

Additionally, wet clutch centrifugal carriers have a wide range of customized torque settings to meet the specific needs of different applications.

Wet clutch centrifugal carriers are also highly reliable.

The wet clutch design features fewer moving parts and a high number of cycles, which reduces wear and tear and ensures a longer service life.

Additionally, the wet clutch centrifugal carrier offers greater efficiency than other torque solutions, providing lower energy costs in the long run.

Whether used in automotive, mining, or industrial applications, wet clutch centrifugal carriers are an ideal option for high-torque applications. With its superior torque capabilities and reliability, wet clutch centrifugal carriers provide an attractive, low-cost power solution for a wide variety of applications.

“Keyword”

“wet centrifugal clutch”

“wet clutch car”

“wet clutch diagram”

“centrifugal clutch lubrication”

“wet clutches”

“centrifugal clutch transmission”